Textile fibers regenerated in Prato have a long history. The protagonists of this story are the “Cenciaioli” Pratesi.

Many Prato people, especially after the Second World War, were Cenciaioli, and those who were not had a job in the Prato textile sector. Every house, every home had a warehouse behind where there was a textile manufacturing inside.

The craft of the cenciaiolo has very distant historical origins that come even from the thirteenth century, but it is in the second post-war period that it reached its peak in this city, due to the scarce raw materials and the need to recover used materials.

The cenciaioli recognized fabrics and fibers with a single touch, dividing them by color and consistency, unleashing and tearing them with bare hands. And from those shreds of rags, rags, a new material was extracted that laid the foundations for the creation of a new yarn and a new fabric

The cenciaioli is more than just a job. It is a noble, refined art, capable of telling the story of those who had worn those used clothes, of creating the new from the old. All according to an economic logic that precedes consumerism: that of common sense.

The regeneration of textile fibers in Prato has a very long history and a great history. After the war, Prato, Biella and Carpi were produced, clothing for all of Italy and for the whole world and surely you too, unknowingly, will have worn a garment produced from fibers, fabrics or regenerated yarns.

The city of Prato has an industrial tradition linked to the regeneration of fibers that dates back to the nineteenth century and although the craft of the cenciaiolo is no longer so widespread, but still present in the Prato area, the companies in the sector that have resisted the crisis are including in the recent years the value of eco-sustainability that distinguishes this activity.

Canciaiolo is an art we are proud to be part of. Personally, I have two generations of chickens behind me, my father and my father’s uncle; and I too learned at an early age, working on “pillow” with my father, the art of the trinket.

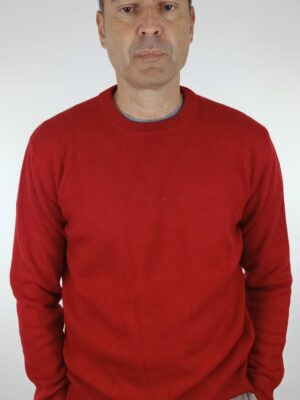

Today, thanks also to the new technologies available, we are realizing a production of sustainable and responsible cashmere yarns and knitwear using regenerated fibers, to create durable, low environmental impact and zero kilometer garments.

The first phase for the creation of regenerated fabrics is precisely that of collecting and selecting old cashmere garments or which are subsequently divided by color.

The collected fabrics are then frayed through the use of particular machines, now industrialized, the card. The new fibers are layered and spun, maintaining their original coloring.

A raw material that gets even more value than the original, which is first transformed into yarn and then also into sweaters, scarves, hats, etc. …

Regenerating brings numerous benefits compared to creating new clothing:

Preserve the environment by reducing the amount of waste produced

Keep limited resources

It reduces production costs and the use of raw materials

Support the local industry

Encourage creativity and innovation

Extends the life of materials

Incentives the economy

The regeneration of textile fibers represents an invaluable resource, a tradition to explore and thanks to which you can experiment with new types of production.

For this innovative approach so linked to its roots in Prato, Hircus Filati remains as well as an Ecocashmere yarn brand that has as its primary objective to offer its customers a quality, economic and low environmental impact product, an alternative to the models that we have used so far, which are the cause of the pollution produced by the fashion world.